- glass@dtglassinc.com

- (503)-650-6373

WHAT MAKES A "FRAMELESS GLASS SHOWER" ...FRAMELESS?

By Shannon Mckinney – DT Glass, Inc.

People hear the term Frameless Glass Shower and think they know what it means, but names can be deceiving. As new products become more popular, they usually become more researched, discussed, and better understood. This doesn’t seem to be the case for frameless glass showers.

Let’s start the discussion with a quiz. Which of these 4 showers is a Frameless Glass Shower?

The answer is E – All of the Above.

Surprised? Here’s the definition:

“Frameless Glass Shower:

Any shower built with 3/8” or 1/2” thick glass”

That’s it. That’s all. Nothing about whether the panels are attached with clips or channel. Nothing about using a header to support a door or oversized panel. From a single panel set in stone, to a grid shower surrounded in metal – anything made with 3/8” or 1/2″ glass is frameless glass.

Why are homeowners, and even some contractors and designers so confused?

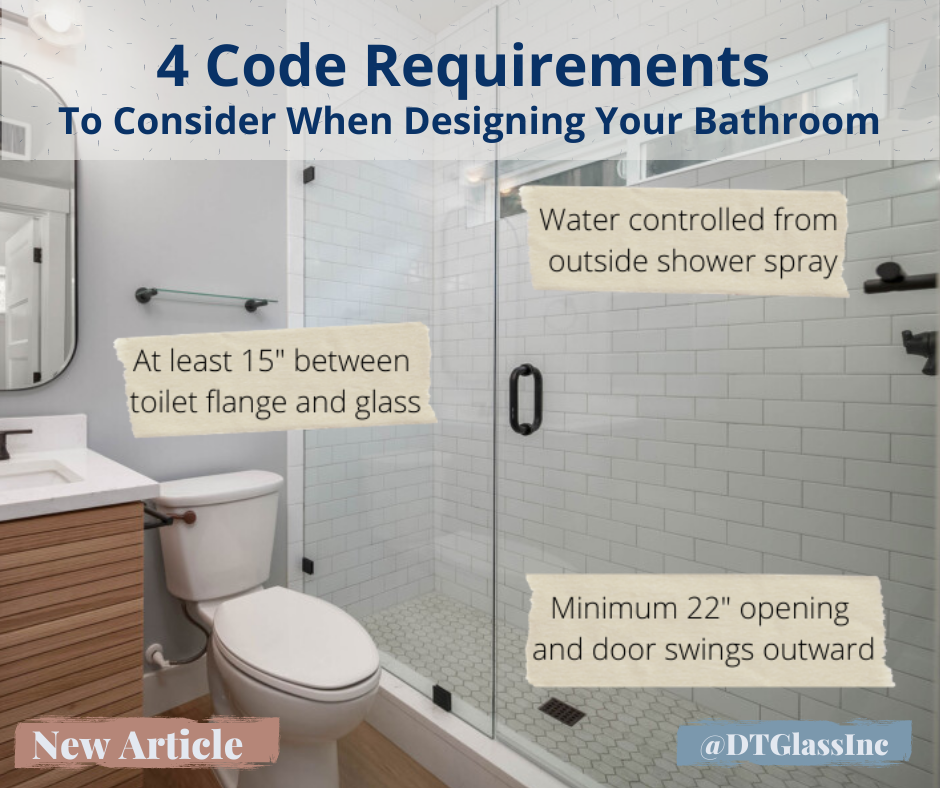

It’s easy to overlook the fact that the metal used to build a framed shower serves TWO distinct and different needs:

1. Add rigidity to the glass

2. Attach the glass to the curb and wall

Meeting the need for rigidity: When showers are built with 3/16” or 1/4″ glass, the glass is too thin to hold itself up. If the glass isn’t surrounded by metal it will bend, break, and be completely unsafe. 3/8” glass is sturdy enough to support itself (up to a certain size), so it doesn’t need to be surrounded in metal.

Frameless glass showers meet the rigidity requirement, but we must still address the attachment dilemma.

Meeting the need for attachment: No matter how thick the glass is, we still need some way to secure it to the wall and curb. It can’t be expected to balance on edge, and it can’t just be glued in (at least not with good long-term results).

I see pictures of showers installed with no metal all over the internet, how do they do it?

The first answer is marketing. There are lots of ways to deceive a consumer: take the picture from an angle that doesn’t show the metal sides and sills, don’t install parts like support bars and seals that the consumer will think are ugly, or photo-shop an installation that is physically impossible.

The second answer is poor craftsmanship. It’s possible to build a shower that looks good today but will not hold up over time. Sometimes people choose aesthetics over engineering, particularly if they know they’ll be gone by the time it falls apart.

I still don’t want a bunch of metal; how can I get that look?

Here are some initial steps to take towards a design that won’t require extra hardware:

Hinge the door directly to the wall – when a door is connected to a glass panel instead of the wall, the panel will need extra hardware to help support the weight of the door.

Keep panels below 34” wide or 20 square feet – large panels will bend and flex at the unsupported corner requiring additional hardware to secure it.

Consider using the ceiling to support large panels – hardware will still be needed to attach the glass to the ceiling, but it’s far less metal than a header or support bar.

Thick stone may be an option for securing a panel, or channel could be partially buried into the tiled walls and curb.

Consider building out walls, or adding posts, so that the glass does not have to span an extra-long opening.

Using the right terminology, and using it correctly, is important. Homeowners, contractors, designers, and glass shops need to know that there is a shared meaning behind the terms they use. Photographs, drawings, and discussing the details can also help to ensure that everyone is working toward the same vision.

At DT Glass, we are committed to breaking through the barriers between homeowners and the showers of their dreams. A cornerstone of this mission is educating and informing our customers. This is the first of a series of blog posts that will discuss all aspects of interior glass, from frameless glass showers to wine rooms. Please watch for future topics and remember we’re always available to discuss your specific project: by phone, through email, or with an on-site consultation.