- glass@dtglassinc.com

- (503)-650-6373

OUT OF LEVEL, OUT OF PLUMB

By Shannon Mckinney – DT Glass, Inc.

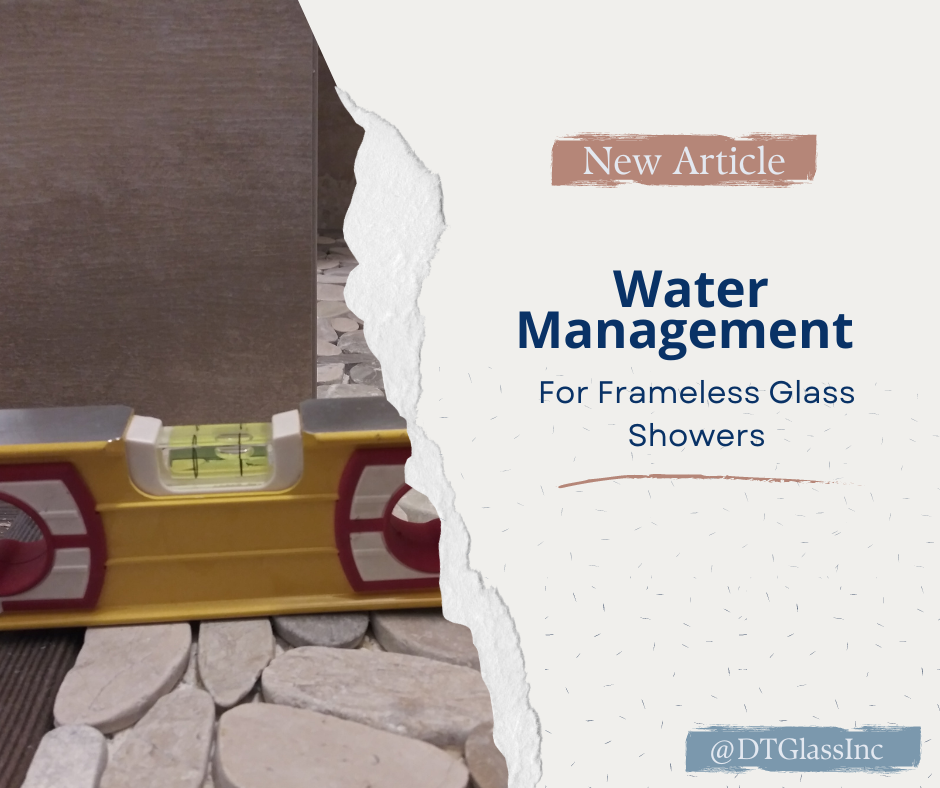

Do you have a shower curb that isn’t level? Shower walls that aren’t perfectly plumb? Not to worry. Almost every shower we measure is out of level or out of plumb. It’s not a matter of poor construction, there are just so many layers of material in a finished shower that the idea of them all stacking up to be perfectly square is nearly impossible. A remodel has even more potential issues because the original construction will have settled over time.

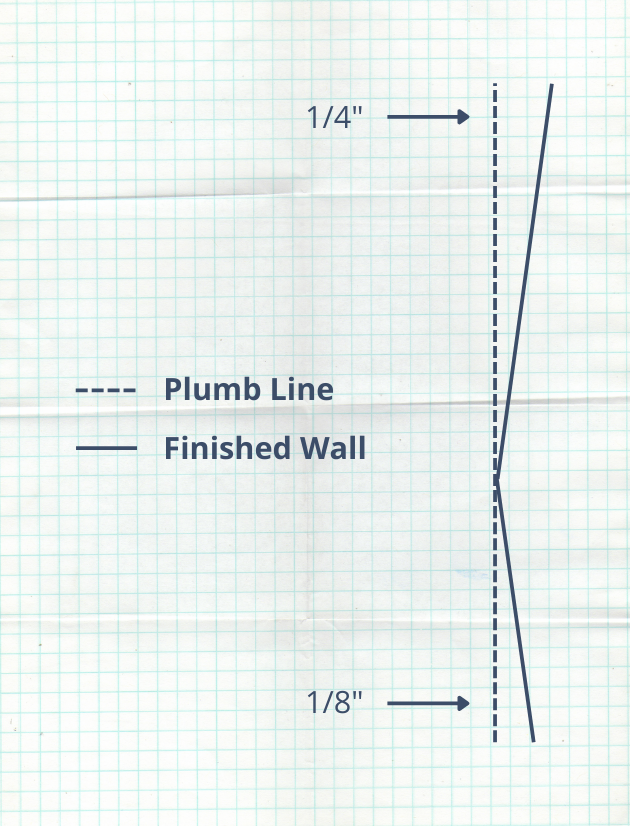

What does it mean for a shower to be out of level or out of plumb? Out of level describes a horizontal surface that slopes up or down as it moves from one side of the measured length to the other. In a shower, this would include the curb, the top of a pony wall, or the top of a bench. Out of plumb describes a vertical surface such as the shower walls. We compare the bottom of the wall to the top of the wall and say it’s “falling in,” “falling out,” or “plumb.” A generic term for either out of level or out of plumb would be to call it “out of square.”

What can be done about an out of level or out of plumb surface? The great thing about frameless glass showers is that they can be custom cut to fit the space. Let’s say, for example, that a shower curb slopes to ¼” lower on the right side than it is on the left. In that case, we would cut the glass so the right-hand side is ¼” taller than the left-hand side to create a glass edge at the bottom that matches the curb. At the shower wall, if we found that the wall was “falling in” at the top and we didn’t do anything about it, then the straight edge of glass placed next to the top of the wall would leave a gap at the bottom of the wall. The solution is to instead cut the glass so that it is narrower at the top than it is on the bottom.

Composite angles within the wall could impact design options. When a wall or curb contain multiple angles, we refer to this as an elbow. An elbow on a wall where wall hinges will be attached could cause an issue. Top and bottom hinges must be installed in a straight line with the pivot points in alignment, otherwise they will work against each other and cause damage to the hinges or the glass. When the wall isn’t straight, we have to use shims or additional backplates to get the hinges to align. This isn’t always possible. An alternative might be to change to pivot style hinges which are installed at the curb and a top attachment point, instead of on the wall. Another option is to place a narrow ½” panel next to the wall, then swing the door from the panel. Attaching a panel to a wall with an elbow is usually not an issue. In the case where an elbow pokes into the glass, we must hand grind the edges. The finish won’t be as good as a machine polish, but since it sits next to the wall it won’t be noticeable.

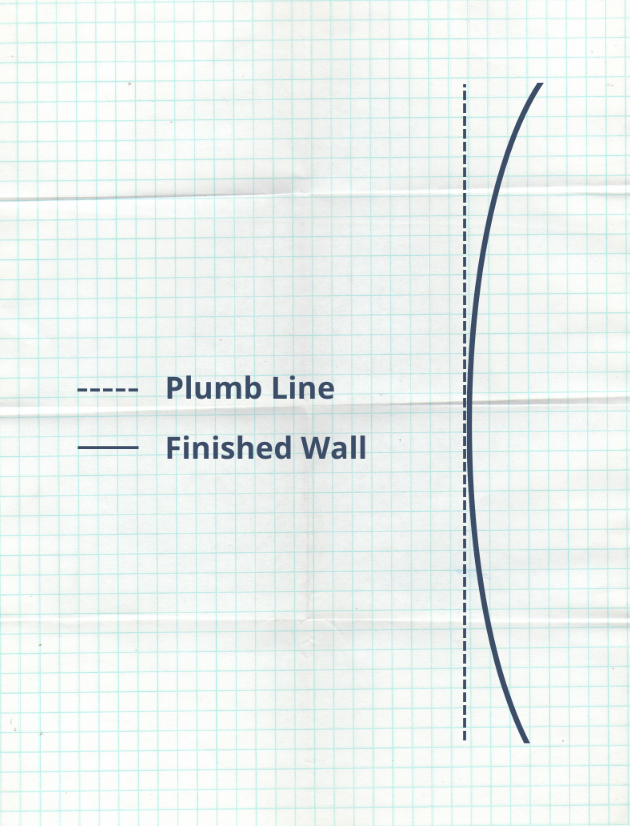

Bows and bellies are inconsistencies we can’t match with the glass. We can tilt and adjust straight edges to fit the bow or belly as close as possible, but gaps will grow larger and smaller along the curve of the wall. We recommend using channel as the attachment method because the metal will be able to flex slightly to the wall and the straight edge of the glass will be hidden in the channel.

What if I’m purchasing pre-made shower glass, but my shower is out of level or out of plumb? As discussed in the blog What Makes a Frameless Shower Frameless, glass is considered frameless when it’s made of 3/8” or 1/2” glass, no matter what other metal is used to attach it to the curb and walls. In pre-made showers, metal is also used to increase or decrease the finished size of the glass and hide gaps. For example, if your finished shower opening is 58-3/4”, you might be ordering glass to fit openings between 58” to 62”. Thick metal wall jambs will make up the distance between the minimum and maximum widths, hide out of square issues, and attach the glass. Metal sills will attach to the curb and stand up tall enough so that bottom gaps won’t result in water leakage. Don’t want thick metal filler pieces around your shower? Then the glass needs to be made to fit your space.

If your shower was custom built, the glass should be too. That’s where custom cut frameless glass comes in. We’ll get your measurements, find any out of level or out of plumb issues and install frameless glass that makes you believe it was built perfectly from the start.